SOLIDWORKS Plastics

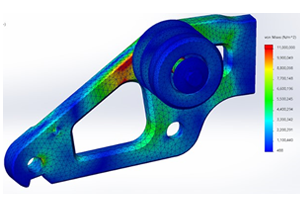

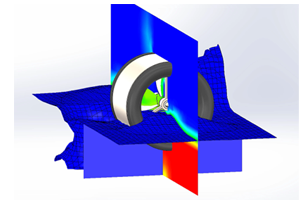

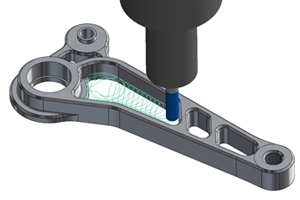

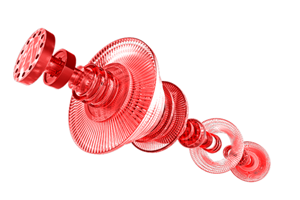

SOLIDWORKS Plastics is a specialized simulation tool tailored for predicting and optimizing the injection molding process for plastic components. With a focus on analyzing part and mold designs, it helps engineers anticipate manufacturing challenges, ensuring more efficient and cost-effective plastic injection molding. Integrated seamlessly with SOLIDWORKS CAD, it provides a comprehensive solution within a familiar design environment.

Why Choose SOLIDWORKS Plastics?

SOLIDWORKS Plastics allows for accurate simulation of the injection molding process, providing insights into potential manufacturing challenges such as sink marks, warpage, and air traps.

Engineers can optimize part and mold designs early in the development process, reducing the need for costly iterations and ensuring that the final plastic components meet performance and quality criteria.

The software includes an extensive material database, enabling users to choose from a wide range of plastics and accurately simulate their behaviour during the injection molding process.

With an intuitive interface, SOLIDWORKS Plastics is accessible to both design engineers and molding experts, facilitating efficient collaboration and enabling users to quickly grasp and apply simulation insights.

Integrated seamlessly with SOLIDWORKS CAD, SOLIDWORKS Plastics offers a cohesive design and simulation workflow, allowing users to easily transition from design to simulation and back, streamlining the plastic part development process.

By simulating the injection molding process early in the design phase, SOLIDWORKS Plastic helps reduce time-to-market for plastic parts. Engineers can identify and address manufacturing issues upfront, minimizing the need for costly design changes and physical prototypes later in the development process.

SOLIDWORKS Plastics Packages

SOLIDWORKS Plastics Standard

Plastics Standard is an entry-level package suitable for users with basic plastic injection molding simulation needs. It provides core functionalities for analyzing the filling phase of the molding process, helping users assess part design and identify potential molding issues early in the development cycle. If your projects involve relatively straightforward injection molding simulations, Plastics Standard may be a cost-effective choice.

SOLIDWORKS Plastics Professional

For more advanced injection molding analyses, the Plastics Professional package is recommended. It builds upon the features of Plastics Standard and introduces additional tools for simulating the packing phase of the molding process. You would be able to optimize Single & Multi-Cavity, Mold layouts including Sprues, Runner and Gates. This package is ideal for users dealing with more intricate molding scenarios and requiring a deeper understanding of the entire injection molding process.

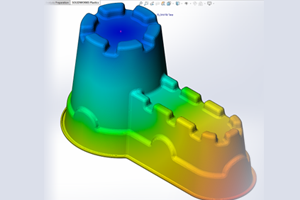

SOLIDWORKS Plastics Premium

The Plastics Premium package is the most advanced option, offering a comprehensive set of tools for highly sophisticated injection molding simulations. It includes everything in Plastics Professional and introduces additional capabilities like Cooling & Warpage phase analysis and Sink Mark Profiles detection. If your projects require in-depth analyses of complex injection molding scenarios, especially those involving part warpage, Plastics Premium is the most suitable choice.

| SOLIDWORKS Plastics Standard | SOLIDWORKS Plastics Professional | SOLIDWORKS Plastics Premium | |

|---|---|---|---|

| Ease of Use | |||

| Design Data Reuse | |||

| Materials Database | |||

| Meshing | |||

| Parallel Computing (Multi-core) | |||

| Filling Phase (1st Stage Injection) | |||

| Instantaneous Fill Time Plot | |||

| Sink Mark Analysis | |||

| eDrawings Support | |||

| Fill Time | |||

| Ease of Fill | |||

| Results Adviser | |||

| Pressure at End of Fill | |||

| Flow Front Temperature | |||

| Temperature at End of Fill | |||

| Shear Rate | |||

| Cooling Time | |||

| Weld Lines | |||

| Air Traps | |||

| Sink Marks | |||

| Frozen Layer Fraction at End of Fill | |||

| Clamp Force | |||

| Cycle Time | |||

| Symmetry Analysis | |||

| Packing Phase (2nd Stage Injection) | |||

| Runner Balancing | |||

| Runner Design Wizard | |||

| Sprues and Runners | |||

| Hot and Cold Runners | |||

| Multi-cavity Molds | |||

| Family Molds | |||

| Mold Inserts | |||

| Volumetric Shrinkage | |||

| Density at End of Pack | |||

| Exports STL, NASTRAN | |||

| Export with Mechanical Properties ABAQUS®, ANSYS, DigiMat® | |||

| Cooling Lines | |||

| Baffles and Bubblers | |||

| Conformal Cooling Channels | |||

| Runner Domain Category | |||

| Sink Mark Profiles | |||

| Mold Temperature at Cooling End | |||

| Displacement Due to Residual Stress |

| SOLIDWORKS PLASTICS STANDARD | SOLIDWORKS PLASTICS PROFESSIONAL | SOLIDWORKS PLASTICS PREMIUM | |

|---|---|---|---|

| CAD INTEGRATION | |||

| SOLIDWORKS Native File | |||

| Associative with SOLIDWORKS | |||

| SOLIDWORKS -EMBEDDED |

| SOLIDWORKS PLASTICS STANDARD | SOLIDWORKS PLASTICS PROFESSIONAL | SOLIDWORKS PLASTICS PREMIUM | |

|---|---|---|---|

| PLASTICS MATERIAL DESIGN | |||

| 4000+ Commercials Plastics | |||

| Customizable |

| SOLIDWORKS PLASTICS STANDARD | SOLIDWORKS PLASTICS PROFESSIONAL | SOLIDWORKS PLASTICS PREMIUM | |

|---|---|---|---|

| Meshing | |||

| Automatic | |||

| Boundary Mesh (shell) | |||

| Solid 3D Mesh | |||

| Global Mesh Refinement | |||

| Local Mesh Refinement |

| SOLIDWORKS PLASTICS STANDARD | SOLIDWORKS PLASTICS PROFESSIONAL | SOLIDWORKS PLASTICS PREMIUM | |

|---|---|---|---|

| Simulation Capabilities | |||

| Filling Phase (1st stage injection) | |||

| Packing Phase (2nd stage) | |||

| Automatic Gate Location(s) | |||

| Instaneous Full Time Plot | |||

| Runner Balancing | |||

| Sink Mark Analysis | |||

| Symmetry Analysis (New!) |

| SOLIDWORKS PLASTICS STANDARD | SOLIDWORKS PLASTICS PROFESSIONAL | SOLIDWORKS PLASTICS PREMIUM | |

|---|---|---|---|

| MOLD GEOMETRY SUPPORT | |||

| Runner Design Wizard | |||

| Sprues and Runners | |||

| Hot & Cold Runners | |||

| Multi-Cavity Molds | |||

| Family Molds | |||

| Cooling Lines | |||

| Baffles & Bubblers | |||

| Conformal Cooling Channels | |||

| Mold Inserts |

| SOLIDWORKS PLASTICS STANDARD | SOLIDWORKS PLASTICS PROFESSIONAL | SOLIDWORKS PLASTICS PREMIUM | |

|---|---|---|---|

| Advanced Simulation Capabilities | |||

| Co-Injection | |||

| Multi-Shot | |||

| Insert Overmolding | |||

| Gas-Assist | |||

| Fiber Analysis | |||

| Reaction Injection Molding (RIM; Thermosets) | |||

| Birefringence | |||

| Valve Gate (sequential injection) | |||

| Cooling Line Analysis | |||

| Conformal Cooling Analysis | |||

| Warpage Analysis |

| SOLIDWORKS PLASTICS STANDARD | SOLIDWORKS PLASTICS PROFESSIONAL | SOLIDWORKS PLASTICS PREMIUM | |

|---|---|---|---|

| Results (partial listing) | |||

| eDrawing Support(New!) | |||

| Fill Time | |||

| Ease of Fill | |||

| Results Advisor | |||

| Nominal Wall Thickness | |||

| Pressure at End of Fill | |||

| Flow Front Temperature | |||

| Temperature at End of Fill | |||

| Shear Stress | |||

| Shear Rate | |||

| Cooling Time | |||

| Weld Lines | |||

| Air Traps | |||

| Sink Marks | |||

| Sink Mark Profiles | |||

| Frozen Layer Fraction at End of Fill | |||

| Clamp Force | |||

| Cycle Time | |||

| Volumetric Shrinkage | |||

| Mold Temperature at Cooling End | |||

| Displacement due to Residue |