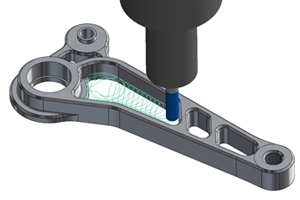

SOLIDWORKS Flow SIMULATION

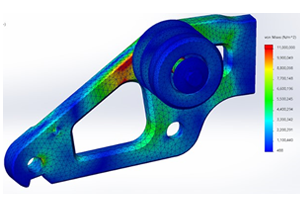

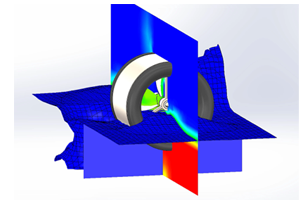

SOLIDWORKS Flow Simulation is a powerful computational fluid dynamics (CFD) tool designed to analyze and simulate fluid flow, heat transfer, and related phenomena within the context of 3D CAD models. With an intuitive interface, engineers can explore and optimize designs by visualizing and understanding the behavior of liquids and gases, making informed decisions to enhance product efficiency and performance.

Why Choose SOLIDWORKS Flow Simulation?

Seamlessly integrates with SOLIDWORKS CAD, allowing for a smooth transition between design and fluid dynamics analysis without the need for data transfer.

The software offers an intuitive interface, simplifying the setup of simulations and providing easy navigation through the analysis process, making it accessible to both experienced CFD analysts and design engineers.

Covers a wide range of fluid dynamics scenarios, including laminar and turbulent flow, heat transfer, and buoyancy effects, enabling engineers to gain comprehensive insights into their designs.

Engineers can visualize fluid flow patterns, temperature distributions, and pressure gradients in real time, facilitating quick and effective decision-making during the design optimization process.

Offers versatility by accommodating both internal and external flow analyses, providing an efficient platform for optimizing designs in diverse industries such as automotive, aerospace, and electronics.

It is validated against experimental data and industry-standard benchmarks to ensure accuracy and reliability. Engineers can trust the results of their simulations to guide design decisions and validate product performance.

SOLIDWORKS Flow Simulation Packages

SOLIDWORKS Flow Simulation

The Flow Simulation package is well-suited for users with fluid dynamics analysis requirements. It includes features for internal and external flow analysis, heat transfer, and general fluid flow simulations. If your projects involve relatively straightforward fluid dynamics scenarios and don't require specialized HVAC or electronic cooling capabilities, Flow Simulation may be a cost-effective choice.

HVAC Module

For professionals working on projects related to heating, ventilation, and air conditioning (HVAC) systems, the HVAC Module is an essential addition. It expands the capabilities of Flow Simulation Standard to address specific HVAC-related simulations. This module is designed to optimize HVAC system designs by simulating factors such as airflow, thermal comfort, and energy efficiency, making it ideal for those in the HVAC industry.

Electronic Cooling Module

If your focus is on electronic cooling applications, the Electronic Cooling module is specifically tailored to address the thermal management challenges associated with electronic components. It provides advanced simulation capabilities for electronic systems, enabling users to analyze heat dissipation, temperature distribution, and optimize the cooling design of electronic devices.

| SOLIDWORKS FLOW SIMULATION | HVAC Module | Electronics Cooling Module | |

|---|---|---|---|

| Ease of Use | |||

| Design Data Reuse | |||

| Multi-Parameter Optimization | |||

| SOLIDWORKS Flow Simulation Capabilities | |||

| Material Database | |||

| Internal | |||

| External | |||

| 2D – 3D | |||

| Heat Conduction in Solids | |||

| Gravity | |||

| Rotation | |||

| Free Surface | |||

| Symmetric | |||

| Gases | |||

| Liquids | |||

| Steam | |||

| Boundary Layer Description | |||

| Mixing Flows | |||

| Non Newtonian Fluids | |||

| Flow Conditions | |||

| Thermal Conditions | |||

| Wall Conditions | |||

| Porous Components | |||

| Visualization | |||

| Results Customization | |||

| Communication & Reporting | |||

| Two-phase (Fluid + Particles) Flows | |||

| Noise Prediction (Steady State and Transient) | |||

| HVAC Conditions | |||

| Tracer Study | |||

| Comfort Parameters | |||

| Electronic Conditions |