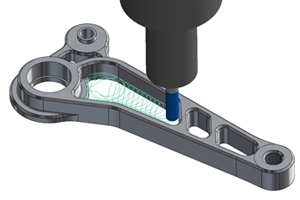

SOLIDWORKS CAM

This powerful tool streamlines the manufacturing process by leveraging information within 3D CAD models. By harnessing the rich content embedded in CAD designs, it accelerates product development while minimizing errors and reducing repetitive manual tasks like CNC machine programming.

Why to choose SOLIDWORKS CAM?

Integrated directly with the design platform, this solution ensures a seamless transition from design to manufacturing. Moreover, by eliminating the need for file conversions, it saves time while maintaining consistent and accurate data throughout the production process.

By automating CNC programming processes, this advanced tool reduces manual errors and accelerates production times. As a result, the manufacturing workflow becomes more streamlined, leading to increased efficiency and productivity.

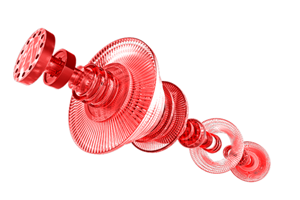

Offering a wide range of advanced machining strategies, this solution enables optimized operations tailored to specific manufacturing needs. Consequently, it enhances machining efficiency, reduces cycle times, and improves surface finishes.

Equipped with simulation and verification features, this tool allows users to identify errors and inefficiencies in machining operations before programs reach the CNC machine. In turn, it ensures accuracy, minimizes scrap, and conserves valuable time and resources.

By optimizing manufacturing workflows, reducing errors, and boosting productivity, this cost-effective solution supports businesses of all sizes. As a result, it helps lower production costs, increase profitability, and maintain a competitive edge in the market.

Featuring an integrated tool library with a wide range of standard tools used in machining operations, this solution allows users to easily select and customize tools based on specific requirements. This ensures accurate tool-path generation and optimal machining performance.

SOLIDWORKS CAM Packages

SOLIDWORKS CAM Standard

Basic milling functionality, including 2.5-axis milling, feature recognition, and area clearing. Tolerance-based machining for optimizing toolpaths based on part tolerances. Suitable for simpler machining operations and smaller businesses with basic needs.

SOLIDWORKS CAM Professional

SOLIDWORKS CAM Professional builds on the Standard version by adding advanced features such as assembly machining, multi-axis indexing (4- and 5-axis), VoluMill technology for high-speed roughing, and turning operations for CNC lathes. This enhanced toolset makes it ideal for more complex machining workflows and better suited for larger businesses with varied production demands. In addition, both the Standard and Professional versions integrate smoothly with the design platform. They streamline manufacturing operations through intelligent automation, along with powerful simulation and verification capabilities that improve precision and overall efficiency.

| SOLIDWORKS CAM Standard | SOLIDWORKS CAM Professional | |

|---|---|---|

| Rule-Based Machining | ||

| Tolerance-Based Machining (TBM) | ||

| Knowledge-Based Machining (KBM) | ||

| Associativity with SOLIDWORKS 3D CAD | ||

| Automatic Feature Recognition (AFR) | ||

| Automate Machine Times | ||

| 3 + 2 Programming | ||

| High-Speed Machining (HSM) | ||

| Turning Capabilities |

| SOLIDWORKS CAM Standard | SOLIDWORKS CAM Professional | |

|---|---|---|

| Rule-Based Machining | ||

| Tolerance-Based Machining (TBM) | ||

| Knowledge-Based Machining (KBM) | ||

| Associativity with SOLIDWORKS 3D CAD | ||

| Automatic Feature Recognition (AFR) | ||

| Automate Machine Times | ||

| 3 + 2 Programming | ||

| High-Speed Machining (HSM) | ||

| Turning Capabilities |